Have you ever bounced on a trampoline and felt that rush of excitement? Now, picture that thrilling bounce combined with the peace of mind that comes from knowing your trampoline is made from the best materials right here in the UK. With in-house manufacturing, every stitch and spring is carefully checked to make sure your trampoline is strong and lasts a long time.

Why does this matter to you? Because when manufacturing happens In-house, you don’t just get a product; you get a masterpiece crafted in your own garden. In this blog, we’ll explore in-house trampoline manufacturing. We’ll cover the process, benefits, and why It’s the best option for you.

What is In-House Manufacturing of Trampolines?

In-house manufacturing of trampolines refers to a process where trampolines are custom-built to cater specifically to the needs and preferences of an individual or organization. Unlike off-the-shelf trampolines that come in standard sizes and shapes, in-house manufactured trampolines offer a personalized touch that considers the user’s specific requirements, available space, and budget. Here’s what sets in-house manufactured trampolines apart:

- Customization: Each trampoline is tailor-made, allowing for specific adjustments in size, shape, and functionality based on the customer’s request. This means you can have a garden trampoline that fits perfectly into the space you have, whether it’s a small backyard or a large commercial gym.

- Versatile Design Options: Depending on its intended use, the location, and the skill level of the users, the design of an in-house manufactured trampoline can vary widely. It may include additional features such as safety nets for protection, padding for extra safety, and adjustable legs to suit varying terrain levels.

- Diverse Applications: While many people associate trampolines with home use, in-house manufactured trampolines are versatile enough for both private and commercial purposes. They can be found in residential properties, theme parks, fitness centers, and educational institutions, providing a source of fun and exercise to a wide audience.

- Durability and Safety: These trampolines are built to last. High-quality materials are selected and combined with proven construction techniques to ensure that each trampoline can handle the demands of frequent and intense use. This focus on durability does not compromise safety, which remains a top priority in the design and manufacturing process.

- Personalized Experience: Owning an in-house manufactured trampoline means enjoying a unique and personalized piece of equipment that enhances the fun and excitement of physical activity for people of all ages and abilities.

In-house manufacturing allows for a level of detail and personalization that mass-produced trampolines simply cannot match, making it an ideal choice for anyone looking to invest in a high-quality, durable, and safe trampoline tailored precisely to their needs.

Benefits of In-house Trampoline Manufacturing

1. Quality Assurance

- Control Over Production: In-house manufacturing facilities have complete control over every stage of the production process. This close oversight ensures that all components meet the highest standards of quality.

- Use of Premium Materials: Manufacturers can select the best materials, ensuring the trampolines are durable, safe, and capable of withstanding both wear and tear and weather conditions.

2. Customization Capabilities

- Tailored Designs: Customers can have trampolines made to specific dimensions and with desired features, which is ideal for unique spaces or particular training needs.

- Personal Touch: In-house manufacturers can directly engage with customers to understand their specific needs, offering a more personalized product.

3. Enhanced Safety

- Rigorous Testing: Trampolines manufactured in-house are subject to strict testing protocols in controlled environments, significantly reducing the risk of defects.

- Safety Innovations: Continuous feedback loops from users and safety inspectors help manufacturers innovate and implement the most effective safety features.

4. Local Economic Benefits

- Job Creation: By manufacturing locally, companies create jobs for the community, contributing to the local economy.

- Community Investment: Money spent on local products, like in-house manufactured trampolines, tends to stay within the community, supporting local development and other business sectors.

5. Reduced Environmental Impact

- Shorter Supply Chains: Local manufacturing reduces the need for long-distance transportation, which lowers carbon emissions and decreases the overall environmental footprint.

- Sustainable Practices: Local producers are more likely to adopt sustainable practices as they are more visible to their communities and consumers who increasingly demand environmentally friendly products.

6. Faster Time to Market

- Quick Adjustments: Being close to the market allows manufacturers to quickly adapt to consumer trends and feedback, reducing the time from product conception to market availability.

- Streamlined Logistics: With reduced shipping times and quicker distribution, companies can offer their products to consumers more rapidly.

Choosing in-house manufactured trampolines means getting a high-quality, customized product while being aware of what’s inside your trampoline!

How Trampolines are Made in-house

The process of making trampolines in-house involves several steps, each essential for creating a high-quality and safe product. Here’s a detailed overview of how trampolines are typically manufactured in-house:

1. Design and Planning

- Customer Consultation: Manufacturers engage with customers to understand their specific needs and preferences, including size, shape, and desired features.

- Prototyping: Designers create prototypes based on customer requirements and feedback, allowing for adjustments before full-scale production.

2. Material Selection

- Quality Assurance: Manufacturers select materials that meet stringent quality standards for durability, strength, and safety.

- Testing: Materials undergo rigorous testing to ensure they can withstand repeated use and varying weather conditions.

3. Fabrication of Components

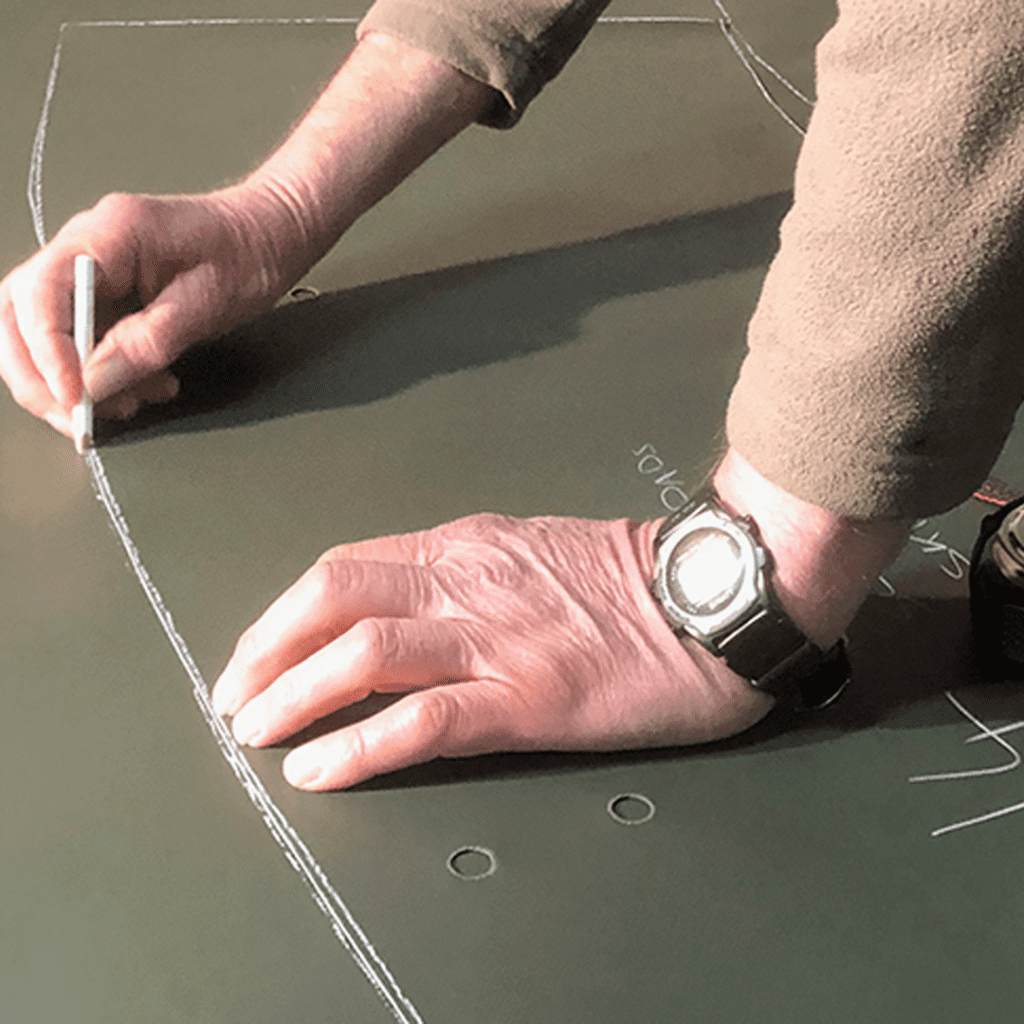

- Frame Construction: Metal frames are fabricated using precision-cutting and welding techniques to ensure stability and structural integrity.

- Springs and Mat Assembly: Springs are attached to the frame, and the mat is securely fastened, ensuring even tension and a smooth jumping surface.

- Safety Enclosure Installation: If included, safety enclosures are installed around the perimeter of the trampoline, providing an additional layer of protection.

4. Quality Control

- Inspection: Each component undergoes thorough inspection to identify any defects or imperfections.

- Testing: Trampolines are subjected to various tests, including weight capacity, durability, and safety checks, to ensure they meet industry standards and exceed customer expectations.

5. Assembly

- Integration of Components: All components are assembled according to the specified design, ensuring proper alignment and functionality.

- Final Checks: A final inspection is conducted to verify that every part is correctly installed and functioning correctly.

6. Customer Support

- Installation Assistance: Manufacturers may offer installation guidance or support to ensure customers can set up their trampolines safely and correctly.

- Warranty Coverage: Most in-house manufactured trampolines come with warranty coverage, providing customers with peace of mind and support in case of any issues.

To produce high-quality trampolines, manufacturers should prioritize safety, durability, and sustainability. This results in a preferred choice for customers seeking a reliable and enjoyable recreational experience.

Top UK-Brand with In- House Trampoline Manufacturing

1. Supertramp Trampolines

Supertramp has been a pioneering brand in the trampoline market, known for its commitment to quality and safety. Founded over 30 years ago, Supertramp was one of the first companies to introduce trampolines as a garden accessory in the UK. They offer a wide range of trampolines, characterized by durable construction, innovative designs, and rigorous safety standards.

2. JumpKing Trampolines

JumpKing is a leading UK brand renowned for its high-quality trampolines manufactured in-house. With over 25 years of experience, JumpKing focuses on combining safety, durability, and fun in its products. Their trampolines feature sturdy frames, premium materials, and innovative safety features, making them a popular choice among families and recreational enthusiasts.

3. Plum® Trampolines

Plum® is another well-established UK brand that manufactures trampolines in-house. With a strong emphasis on safety and durability, Plum® trampolines are designed to withstand outdoor elements while providing endless hours of bouncing fun. Their range includes trampolines of various sizes and styles, catering to different age groups and usage requirements.

Conclusion

In-house manufacturing of trampolines in the UK significantly enhances product quality and safety while supporting local industry and sustainability. This method ensures consumers receive durable, safe, and tailored products, and also promotes job creation and reduces environmental footprints. For those seeking reliability and community benefit, choosing trampolines made in-house in the UK is an excellent decision.